Organizations differ from consumers in terms of their buying behavior. Purchase decisions in most firms follow a specific process, which is more or less standardized and formalized, in contrast to consumer purchase decisions. We shed light on the B2B purchasing process and explore the different phases through which organizations go when deciding what, where, when and at what price to buy.

Table of Contents

Types of B2B Purchasing Situations

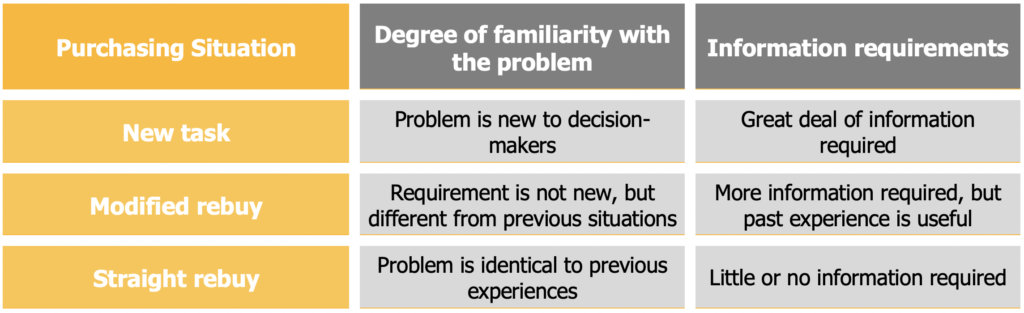

Organizational purchasing decisions vary in terms of the nature of the offering, the frequency and the value of the purchases made, their strategic impact, and the type of relationship with suppliers. Robinson et al. (1967) suggest that there are three main types of purchasing situations. Each of these situations have specific characteristics, which are explained below.

- New task – In this situation, the firm is purchasing something for the first time. The risk involved in the purchase is inevitable high, as there is little experience of the offering or of the relevant suppliers. Consequently the number of people involved in the purchasing process and decision is large. Likewise, the time needed for processing all the information and making a decision is rather long.

- Modified rebuy – When a firm buys something that is has already purchased in the past, we refer to it as modified rebuy. In this situation, uncertainty is reduced, although not eliminated. Therefore, the organization may request that certain modifications be made for purchased in the future, such as adjustments to product specifications, price levels or delivery. Due to the reduced uncertainty and complexity, fewer people are involved in the decision-making process than in the new task situation.

- Straight rebuy – In this situation, the firm purchases some item on a routine basis. Frequently, it uses a list of approved suppliers to avoid uncertainty. The products are usually those that an organization consumes in order to keep operating, such as office stationary, or low-value materials used within operations. Usually, no people except for the purchasing department are involved in the decision-making process, unless a supplier change occurs or renegotiations are needed. This, however, would then be referred to again as a modified rebuy situation.

B2B Purchasing Process

Organizational purchasing behaviour can be broken down into a series of sequential activities through which organizations proceed when deciding what, where, when and at what price to buy. Robinson et al. (1967) referred to these as ‘buying stages’, or ‘buyphases’.

The complete sequence of buyphases is particular to the new task situation. That means, only in new task situations, firms go through all steps of the B2B purchasing process. Many of the steps are skipped or compressed according to the complexity of the offering when either a modified rebuy or straight rebuy situation is encountered.

Need/Problem Recognition

The need recognition phase is about the identification of a gap between the benefits that a firm is experiencing now and the benefits that it would like to have. For example, when a new product is to be produced, there is a gap between having the necessary materials and being out of stock and unable to produce it. The first decision therefore is about how to close this gap. There are two broad options for this: outsourcing the whole or parts of the production process; or producing the product oneself.

Product Specification

The second step of the B2B purchasing process is about specifying the characteristics of the product. After identifying a problem, the firm needs to determine the desired characteristics of the product needed to resolve the problem. This may take the form of either a general functional description, or a more detailed analysis and the creation of a detailed technical specification for a particular proposition. For instance, questions that need to be answered could look like this: What sort of engine is required for a new airplane? What thrust is it expected to achieve? How much will it cost to service? This phase is an important part of the B2B purchasing process because, if executed properly, it will narrow the supplier search and thus save costs. The results of the functional and detailed specifications are often summarized in a purchase order specification.

Supplier and Product Search

At this stage of the B2B purchasing process, the buyer actively seeks suppliers who can supply the necessary product or required materials to build it. There are two main issues at this point: first, will the product match the specification and the required performance standards? Second, will the potential supplier meet the other organizational requirements, such as experience, reputation and credit rating? In most circumstances, firms will review the market and their internal sources of information, and arrive at a decision based on rational criteria to reduce uncertainty and risk. By working with suppliers who are well-known, or those of whom the organization has direct experience, risk and uncertainty can be reduced substantially.

Evaluation of Proposals

Depending on the complexity and value of the potential order(s), the proposal is a vital part of the B2B purchasing process and should be prepared professionally. The proposals from the shortlisted organizations are reviewed considering two major criteria: 1) the purchase order specification; and 2) an evaluation of the supplying organization. If the potential supplier is already a part of the network (referred to as a ‘preferred supplier’), then little search and review time is needed. If the proposed supplier is not a preferred supplier, a review may be necessary to establish whether it will be appropriate (in terms of price, delivery, and service) and whether there is the potential for a long-term relationship.

Supplier Selection

The firm or purchasing department will next normally undertake a supplier analysis and use a variety of decision criteria, according to the particular type of item sought. Instead of considering only one supplier, many organizations choose to select multiple suppliers. Thereby, supplier risk can be limited. The major disadvantage is that this approach can fail to drive costs as low as possible, because the discounts derived from volume sales are not achieved. However, many organizations prefer to use only a single supplier. All purchases are made from the single source until circumstances change to such a degree that the firm’s needs are no longer satisfied. An increasing number of firms choose to enter long-term relationships with a limited number or even single-source suppliers. The objective is to build a profitable long-term buyer–supplier relationship, to work together to build quality, and to help to achieve each other’s goals.

Evaluation

The B2B purchasing process finishes with the evaluation phase. In this phase, the order is written against the selected supplier, which is then monitored and evaluated against criteria such as responsiveness to enquiries, modifications to the specification, and timing of deliveries. For instance, it may happen that the product reaches the stated specification, but fails to satisfy the original need. In this case, the specification needs to be rewritten before any future orders are placed.

Many variables exist that have an impact on the purchasing process. For instance, changes in the environment of the organization may influence the process, changing both the nature of decisions and the way in which they are made. Therefore, the B2B purchasing process should not be considered as a one-time approach, but rather be used as a continuous, flexible cycle that is frequently repeated.